Products

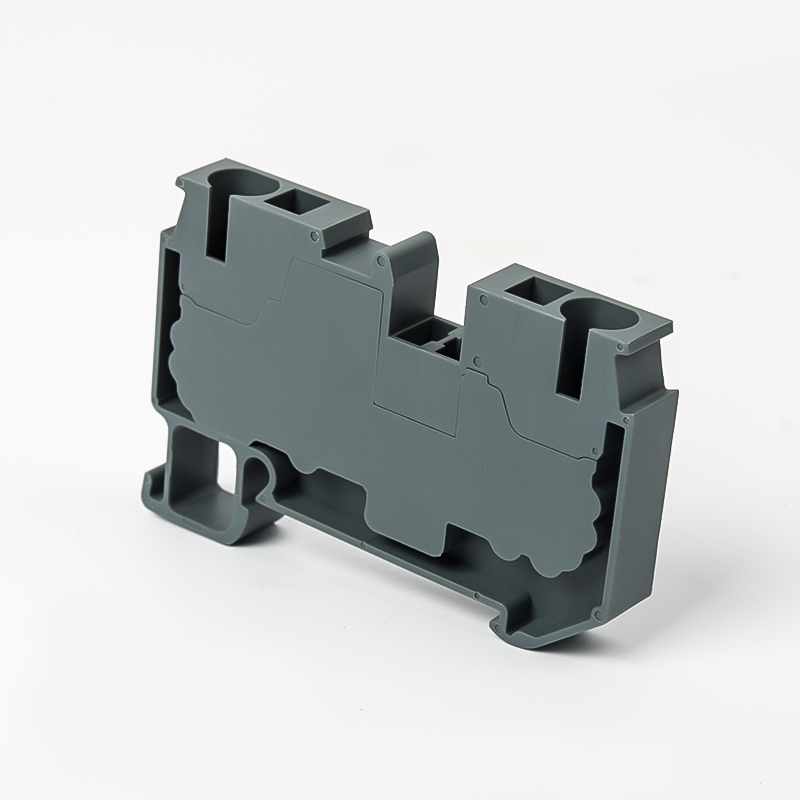

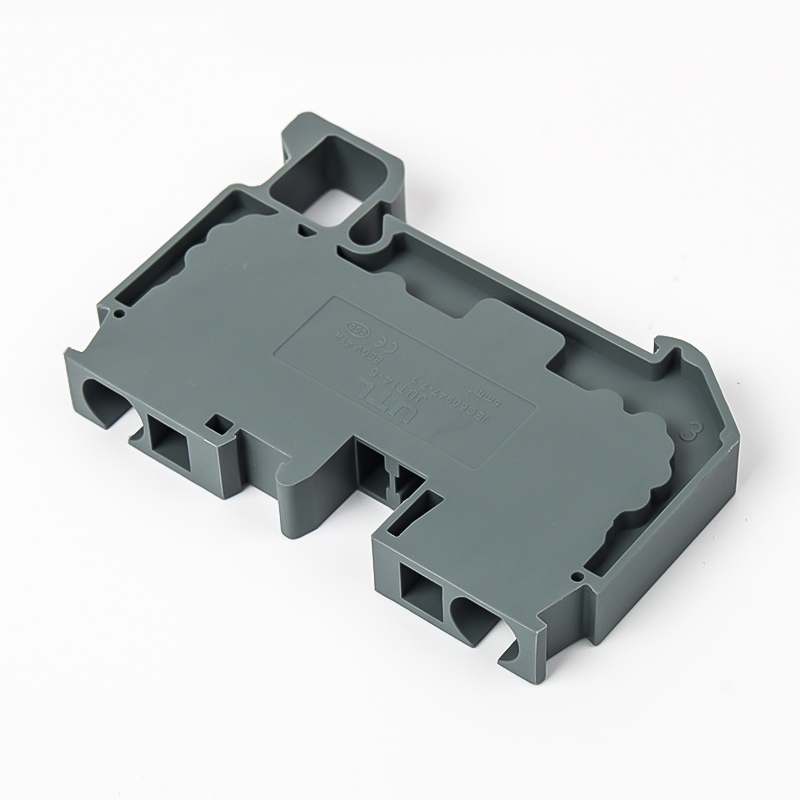

JUT14-6 Spring lead throung-type landing Din rail connector Terminal Block Cable

Advantage

The Push-in direct connection technology make the insertion forces reduced by up to 50 percent and tool-free wiring, enable the conductors to be inserted easily and directly.

Made from engineering flame retardants nylon PA66 with brass screw metal.

●The Push-in connection terminal blocks are characterized by easy and tool-free wiring of conductors with ferrules or solid conductors.

●The compact design and front connection enable wiring in a confined space.

●In addition to the testing facility in the double function shaft, all terminal blocks provide an additional test connection.

●With universal foot which can be installed on Din Rail NS 35.

●It can connect two conductors with ease, even large conductor cross sections are not a problem.

●Electric potential distribution can use fixed bridges in the terminal center.

●All types of accessories: End cover, End Stopper, Partition plate, marker trip, fixed bridge, insertion bridge, etc.

Details parameters

|

Details parameters: |

||||

|

Product Image |

|

|

|

|

|

Product number |

JUT14-6/DK/GY |

JUT14-6/1-2/DK/GY |

JUT14-6 PE |

JUT14-6/1-2 PE |

|

product type |

Rail wiring distribution block |

Rail wiring distribution block |

Rail wiring distribution block |

Rail wiring distribution block |

|

Mechanical structure |

Push-in spring connection |

Push-in spring connection |

Push-in spring connection |

Push-in spring connection |

|

layers |

1 |

1 |

1 |

1 |

|

Electric potential |

1 |

1 |

1 |

1 |

|

connection volume |

2 |

3 |

2 |

3 |

|

Rated cross section |

6 mm2 |

6 mm2 |

6 mm2 |

6 mm2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Rated current |

40A |

40A |

40A |

40A |

|

Rated voltage |

800V |

800V |

800V |

800V |

|

open side panel |

Yes |

Yes |

no |

no |

|

grounding feet |

no |

no |

Yes |

Yes |

|

other |

The connecting rail needs to install the rail foot F-NS35 |

The connecting rail needs to install the rail foot F-NS35 |

The connecting rail needs to install the rail NS 35/7,5 or NS 35/15 |

The connecting rail needs to install the rail NS 35/7,5 or NS 35/15 |

|

Application field |

Widely used in electrical connection, industrial |

Widely used in electrical connection, industrial |

Widely used in electrical connection, industrial |

Widely used in electrical connection, industrial |

|

color |

(gray)、(dark gray)、(green)、(yellow)、(cream)、(orange)、(black)、(red)、(blue)、(white)、(purple)、(Brown)、customizable |

(gray)、(dark gray)、(green)、(yellow)、(cream)、(orange)、(black)、(red)、(blue)、白色(white)、(purple)、(Brown)、customizable |

Green and Yellow |

Green and Yellow |

|

|

||||

|

Stripping length |

14mm |

14mm |

14mm |

14mm |

|

Rigid Conductor Cross Section |

0.5-10mm² |

0.5-10mm² |

0.5-10mm² |

0.5-10mm² |

|

Flexible conductor cross section |

0.5-6mm² |

0.5-6mm² |

0.5-6mm² |

0.5-6mm² |

|

Rigid Conductor Cross Section AWG |

24-8 |

0.5-6mm² |

0.5-6mm² |

24-8 |

|

Flexible Conductor Cross Section AWG |

24-10 |

24-10 |

24-10 |

24-10 |

|

|

||||

|

size (this is the dimension of the JUT14-6 carrying rail foot F-NS35 installed on the rail) |

|

|||

|

thickness |

8.2mm |

8.2mm |

8.2mm |

8.2mm |

|

width |

61.2mm |

78mm |

61.2mm |

78mm |

|

high |

41.2mm |

41.7mm |

41.2mm |

41.7mm |

|

NS35/7.5 high |

48.7mm |

49.2mm |

48.7mm |

49.2mm |

|

NS35/15 high |

56.2mm |

56.7mm |

56.2mm |

56.7mm |

|

NS15/5.5 high |

|

|

|

|

|

|

||||

|

Material properties |

|

|||

|

Flame retardant grade, in line with UL94 |

V0 |

V0 |

V0 |

V0 |

|

Insulation Materials |

PA |

PA |

PA |

PA |

|

Insulation material group |

I |

I |

I |

I |

|

|

||||

|

IEC Electrical parameters |

|

|||

|

standard test |

IEC 60947-7-1 |

IEC 60947-7-1 |

IEC 60947-7-1 |

IEC 60947-7-1 |

|

Rated voltage(III/3) |

800V |

800V |

800V |

800V |

|

Rated current(III/3) |

40A |

40A |

40A |

40A |

|

Rated surge voltage |

6kv |

6kv |

6kv |

6kv |

|

Overvoltage class |

III |

III |

III |

III |

|

pollution level |

3 |

3 |

3 |

3 |

|

|

||||

|

Electrical performance test |

|

|||

|

Surge Voltage Test Results |

Passed the test |

Passed the test |

Passed the test |

Passed the test |

|

Power frequency withstand voltage test results |

Passed the test |

Passed the test |

Passed the test |

Passed the test |

|

|

|

|

|

|

|

Temperature rise test results |

Passed the test |

Passed the test |

Passed the test |

Passed the test |

|

|

||||

|

environmental conditions |

|

|||

|

Ambient temperature (operating) |

-60 °C — 105 °C (Maximum short-term operating temperature, electrical characteristics are relative to temperature.) |

-60 °C — 105 °C (Maximum short-term operating temperature, electrical characteristics are relative to temperature.) |

-40℃~+105℃(Depends on the derating curve) |

-40℃~+105℃(Depends on the derating curve) |

|

Ambient temperature (storage/transport) |

-25 °C — 60 °C (short term (up to 24 hours), -60 °C to +70 °C) |

-25 °C — 60 °C (short term (up to 24 hours), -60 °C to +70 °C) |

-25 °C - 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) |

-25 °C - 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) |

|

Ambient temperature (assembled) |

-5 °C — 70 °C |

-5 °C — 70 °C |

-5 °C — 70 °C |

-5 °C — 70 °C |

|

Ambient temperature (execution) |

-5 °C — 70 °C |

-5 °C — 70 °C |

-5 °C — 70 °C |

-5 °C — 70 °C |

|

Relative Humidity (Storage/Transportation) |

30 % — 70 % |

30 % — 70 % |

30 % — 70 % |

30 % — 70 % |

|

|

||||

|

Environmental friendly |

|

|||

|

RoHS |

No excessive harmful substances |

No excessive harmful substances |

No hazardous substances above threshold values |

No hazardous substances above threshold values |

|

|

||||

|

Standards and Specifications |

|

|||

|

Connections are standard |

IEC 60947-7-1 |

IEC 60947-7-1 |

IEC 60947-7-1 |

IEC 60947-7-1 |