Products

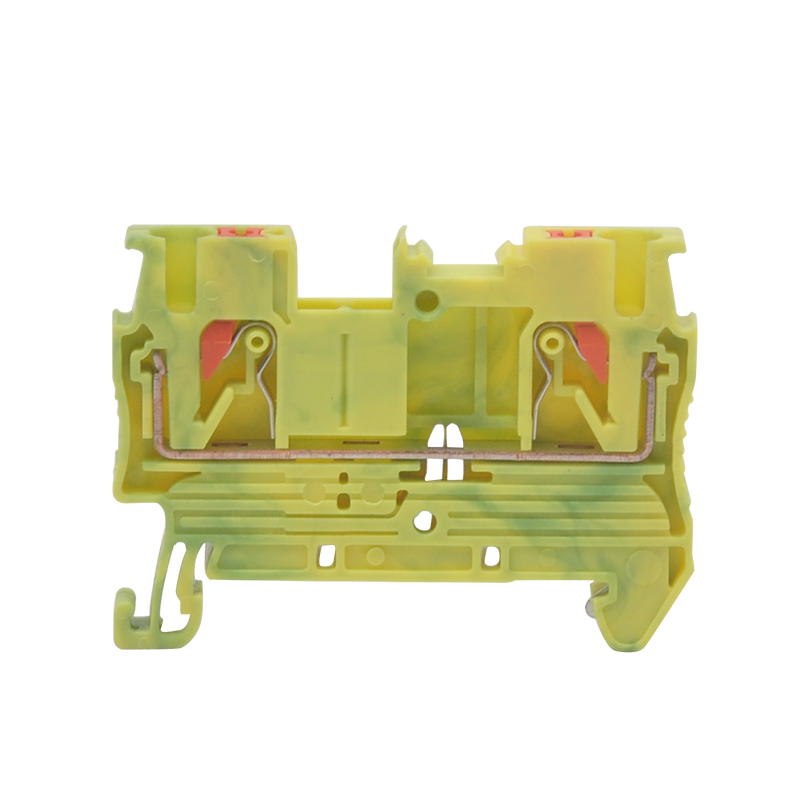

UPT-2.5/3 (triple layers Low Voltage Power Insulated Spring Cage high quality terminal block)

Advantage

The Push-in direct connection technology make the insertion forces reduced by up to 50 percent and tool-free wiring, enable the conductors to be inserted easily and directly.

Made from engineering flame retardants nylon PA66 with brass screw metal.

Made from engineering flame retardants nylon PA66 with brass screw metal.

●The Push-in connection terminal blocks are characterized by easy and tool-free wiring of conductors with ferrules or solid conductors.

●The compact design and front connection enable wiring in a confined space.

●In addition to the testing facility in the double function shaft, all terminal blocks provide an additional test connection.

●With universal foot which can be installed on Din Rail NS 35.

●It can connect two conductors with ease, even large conductor cross sections are not a problem.

●Electric potential distribution can use fixed bridges in the terminal center.

●All types of accessories: End cover, End Stopper, Partition plate, marker trip, fixed bridge, insertion bridge, etc.

Details parameters

| Product Description | |||||

| Product Image | |||||

| Product Number | UPT-2.5/2 | UPT-2.5/1-2 | UPT-2.5/2-2 | UPT-2.5/3 | UPT-2.5/3PE |

| Product Type | Rail wiring distribution block | Rail wiring distribution block | Rail wiring distribution block | Rail wiring distribution block | Rail wiring distribution block |

| Mechanical Structure | Push-in spring connection | Push-in spring connection | Push-in spring connection | Push-in spring connection | Push-in spring connection |

| Layers | 2 | 1 | 1 | 3 | 3 |

| Electric Potential | 1 | 1 | 1 | 3 | 3 |

| Connection Volume | 2 | 1 | 1 | 6 | 6 |

| Rated Cross Section | 2.5 mm2 | 2.5 mm2 | 2.5mm2 | 2.5 mm2 | 2.5 mm2 |

| Rated Current | 22A | 24A | 24A | 20A | |

| Rated Voltage | 500V | 800V | 800V | 500V | |

| Open Side Panel | Yes | Yes | Yes | no | no |

| Grounding Feet | no | no | no | no | no |

| Other | The connecting rail needs to install the rail foot F-NS35 | The connecting rail needs to install the rail foot F-NS35 | The connecting rail needs to install the rail foot F-NS35 | The connecting rail needs to install the rail foot F-NS35 | The connecting rail needs to install the rail NS 35/7,5 or NS 35/15 |

| Application Field | Widely used in electrical connection, industrial | Widely used in electrical connection, industrial | Widely used in electrical connection, industrial | Widely used in electrical connection, industrial | Widely used in electrical connection, industrial |

| Color | (gray)、(dark gray)、(green)、(yellow)、(cream)、(orange)、(black)、(red)、(blue)、(white)、(purple)、(Brown)、customizable | (gray)、(dark gray)、(green)、(yellow)、(cream)、(orange)、(black)、(red)、(blue)、(white)、(purple)、(Brown)、customizable | (gray)、(dark gray)、(green)、(yellow)、(cream)、(orange)、(black)、(red)、(blue)、(white)、(purple)、(Brown)、customizable | (gray)、(dark gray)、(green)、(yellow)、(cream)、(orange)、(black)、(red)、(blue)、(white)、(purple)、(Brown)、customizable | (green)、 |

| Wiring Data | |||||

| Line Contact | |||||

| Stripping Length | 8mm — 10mm | 8mm — 10mm | 8mm — 10mm | 8mm — 10mm | 8mm — 10mm |

| Rigid Conductor Cross Section | 0.14mm² — 4mm² | 0.14mm² — 4mm² | 0.14mm² — 4mm² | 0.2mm² — 4mm² | 0.2mm² — 4mm² |

| Flexible Conductor Cross Section | 0.14mm² — 2.5mm² | 0.14mm² — 2.5mm² | 0.14mm² — 2.5mm² | 0.2mm² — 4mm² | 0.2mm² — 4mm² |

| Rigid Conductor Cross Section AWG | 26-12 | 26-12 | 26-12 | 26-12 | 26-12 |

| Flexible Conductor Cross Section AWG | 26-14 | 26-14 | 26-14 | 26-14 | 26-14 |

| Size (This Is The Dimension Of The UPT-2.5 Carrying Rail Foot F-NS35 Installed On The Rail) | |||||

| Thickness | 5.2mm | 5.2mm | 5.2mm | 102.2mm | 102.2mm |

| Width | 48.5mm | 60.5mm | 72.2mm | 5.2mm | 5.2mm |

| High | 45.8mm | 35.2mm | 35.3mm | 56.45mm | 56.45mm |

| NS35/7.5 High | 55 mm | 44mm | 44.3mm | 31.1mm | 31.1mm |

| NS35/15 High | 47.5mm | 36.5mm | 36.8mm | 38.6mm | 38.6mm |

| NS15/5.5 High | |||||

| Material Properties | |||||

| Flame Retardant Grade, In Line With UL94 | V0 | V0 | V0 | V0 | V0 |

| Insulation Materials | PA | PA | PA | PA | PA |

| Insulation Material Group | I | I | I | I | I |

| IEC IEC Electrical Parameters | |||||

| Standard Test | IEC 60947-7-1 | IEC 60947-7-1 | IEC 60947-7-1 | IEC 60947-7-1 | IEC 60947-7-1 |

| Rated Voltage(III/3) | 500V | 800V | 800V | 500V | |

| Rated Current(III/3) | 22A | 24A | 24A | 20A | |

| Rated Surge Voltage | 8kv | 8kv | 8kv | 6kv | 6kv |

| Overvoltage Class | III | III | III | III | III |

| Pollution Level | 3 | 3 | 3 | 3 | 3 |

| Electrical Performance Test | |||||

| Surge Voltage Test Results | Passed the test | Passed the test | Passed the test | Passed the test | Passed the test |

| Power Frequency Withstand Voltage Test Results | Passed the test | Passed the test | Passed the test | Passed the test | Passed the test |

| Temperature Rise Test Results | Passed the test | Passed the test | Passed the test | Passed the test | Passed the test |

| Environmental Conditions | |||||

| Ambient Temperature (Operating) | -60 °C — 105 °C (Maximum short-term operating temperature, electrical characteristics are relative to temperature.) | -60 °C — 105 °C (Maximum short-term operating temperature, electrical characteristics are relative to temperature.) | -60 °C — 105 °C (Maximum short-term operating temperature, electrical characteristics are relative to temperature.) | -40℃~+105℃(Depends on the derating curve) | -40℃~+105℃(Depends on the derating curve) |

| Ambient Temperature (Storage/Transport) | -25 °C — 60 °C (short term (up to 24 hours), -60 °C to +70 °C) | -25 °C — 60 °C (short term (up to 24 hours), -60 °C to +70 °C) | -25 °C — 60 °C (short term (up to 24 hours), -60 °C to +70 °C) | -25 °C - 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) | -25 °C - 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) |

| Ambient Temperature (Assembled) | -5 °C — 70 °C | -5 °C — 70 °C | -5 °C — 70 °C | -5 °C — 70 °C | -5 °C — 70 °C |

| Ambient Temperature (Execution) | -5 °C — 70 °C | -5 °C — 70 °C | -5 °C — 70 °C | -5 °C — 70 °C | -5 °C — 70 °C |

| Relative Humidity (Storage/Transportation) | 30 % — 70 % | 30 % — 70 % | 30 % — 70 % | 30 % ... 70 % | 30 % — 70 % |

| Environmental Friendly | |||||

| RoHS | No excessive harmful substances | No excessive harmful substances | No excessive harmful substances | No hazardous substances above threshold values | No hazardous substances above threshold values |

| Standards And Specifications | |||||

| Connections Are Standard | IEC 60947-7-1 | IEC 60947-7-1 | IEC 60947-7-1 | IEC 60947-7-1 | IEC 60947-7-1 |